The Entaco Medical team can contribute and support medical device projects from concept to launch – Including design and regulatory services working in collaboration with proven 3rd party service providers.

Our experienced technical team can contribute and undertake validation activities to support CE Marking, 510k or PMA submissions. Concurrent engineering and quality planning enable Entaco Medical to fully integrate our sub-contract processes into any supply chain.

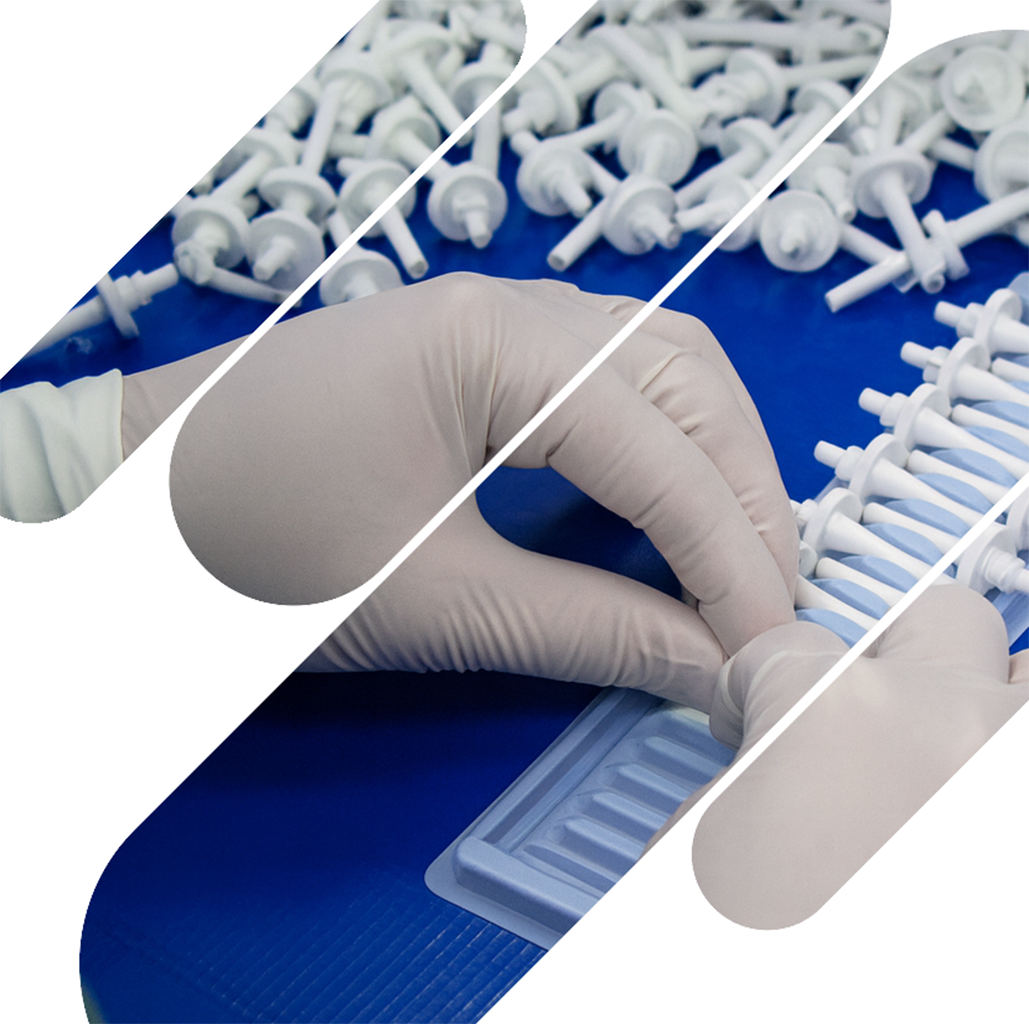

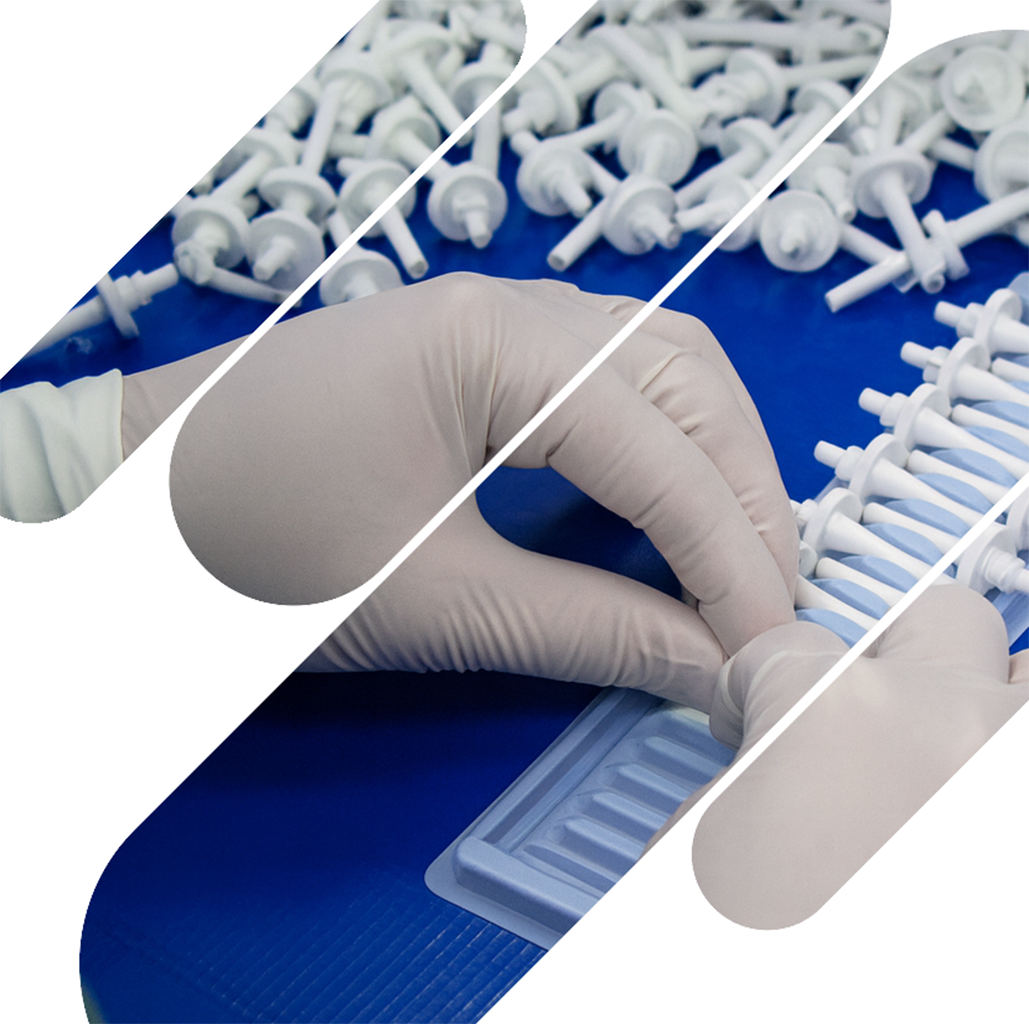

ISO 7 (Class 10,000) validated cleanroom suites are environmentally controlled, rigorously maintained and continuously monitored to ensure to highest degree of compliance to ISO 14644 – Cleanrooms and associated controlled environments. Our planned workflow and compliance with the requirements of our QMS ensure all cleaning and packing activities are carefully controlled.

We have the ability to clean, pack and label devices providing a total supply solution for customer products. All equipment is validated and maintained within the QMS. Blister and Peel Pouch packaging options are available to suit customer preferences. In process packaging testing is routinely performed to demonstrate consistent seal Integrity. Entaco Medical can also manage packaging design concepts working with the customer to achieve exact requirements.

At Entaco Medical, we provide a flexible one-off contract packaging service within our controlled environments, ensuring the highest standards of quality and cleanliness. This service is ideal for customers requiring short production runs, bespoke packaging solutions, sample preparation, or specialist kit assembly. Operating under ISO 13485 and ISO 9001 standards, we maintain full compliance, traceability, and product integrity throughout the process. Our experienced team works closely with clients to deliver tailored packaging solutions, offering a reliable and efficient service with complete quality oversight from start to finish.

Prior to supply, Entaco Medical can outsource all sterilisation processes to industry approved suppliers for Gamma Irradiation, Ethylene oxide (ETO) and Gas Plasma Sterilisation, providing a terminally sterile device ready for use.

Dependent on each customer’s needs, our Contract Manufacturing Service can incorporate:

Quality Assurance & Regulatory Compliance

At Entaco Medical, we specialise in subcontract manufacturing for the medical device and single-use consumable industries, operating under a mature and rigorously maintained ISO 13485-certified Quality Management System and FDA registration. Our facilities and processes are fully aligned with 21 CFR Part 820 and applicable Good Manufacturing Practices (GMP), ensuring the consistent production of high-quality, compliant components and finished products.

As a contract manufacturer, we focus on:

We work in close partnership with our customers to meet their specifications and regulatory obligations, supporting their product compliance through reliable, repeatable manufacturing outcomes. Our role is to ensure that what we manufacture consistently meets the highest standards—on time, every time.